Experience superior surface texture and stiffness with PET-CF17, the high-speed 3D printing material that delivers strength without moisture sensitivity concerns. This carbon fiber reinforced filament excels at rapid prototyping, offering exceptional print quality and dimensional accuracy. Combining the best of strength, speed, and surface finish into one exceptional composite filament.

Pairs well with

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

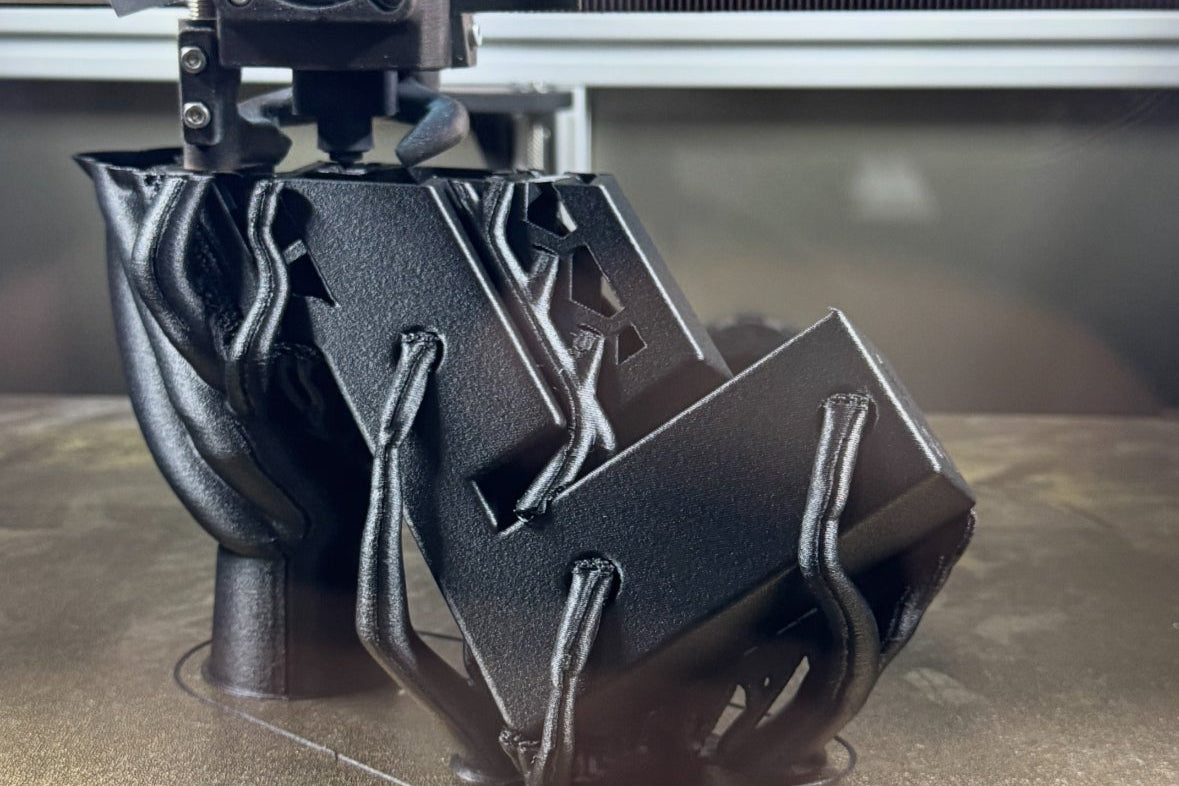

Built to Print. Engineered to Last.

From prototyping to production, LANDR delivers functional parts fast — with no tooling, no lock-in, and no fluff.

Made for industry. Priced for reality.

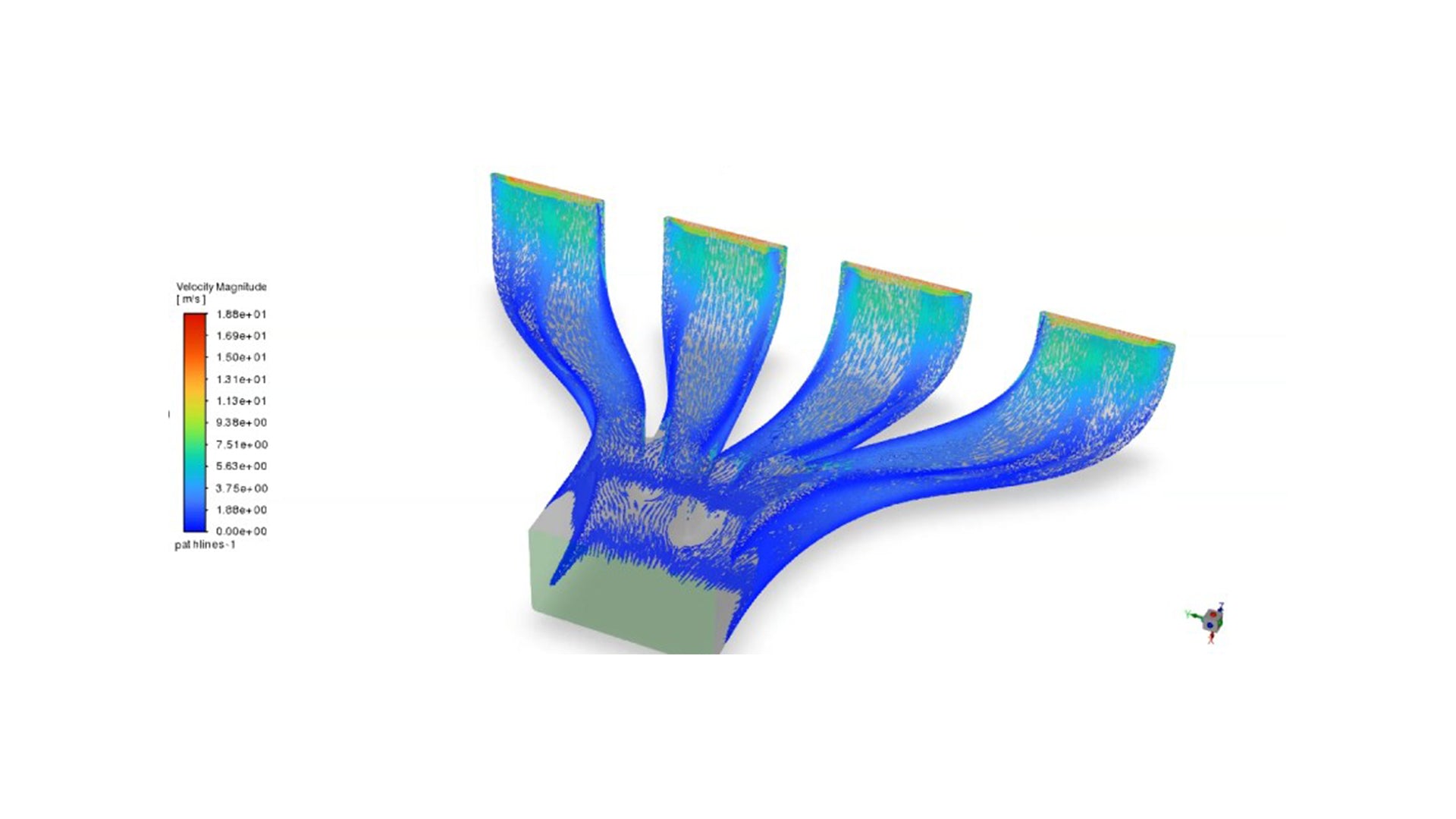

CFD Optimised Cooling

Engineered with CFD for optimised airflow, thermal control, and consistent print performance.

Key Facts about the LANDR 500

Build Volume

500 x 500 x 500 mm

Extrusion System

1.75mm Single Nozzle. Upgradable to Dual Extrusion

Temperatures

Hot End - 500*C

Print Bed - 140*C

CHamber Temp - 100*C

Print Speeds

Up to 800mm/s

FAQs

Please read our FAQs page to find out more.

What size parts can I print?

The LANDR 500 offers a generous build volume 500x500x500m. Allowing you to produce larger single parts or batch multiple components in one run -increasing efficiency and reducing turnaround times.

What materials can I print with?

The LANDR 500 Filament supports a wide range of general & engineering-grade thermoplastics, including:

PLA, PETG, PETG-CF, ABS, ABS-CF, ABS-GF, PA (Nylon), PA-CF, PA6-CF, PA12-CF, PAHT-CF, TPE, PC-ABS, PCTG, PPS-CF, PPA-CF, PPA, PPS, ASA, ASA-CF, PP, PP-GF, PP-GF, PC, TPU, + more!

It’s an open-material system, so you're free to use third-party filaments that suit your performance and budget needs.

What kind of support is included?

Every LANDR 500 comes with full UK-based support in-person for the first 2 years & then Lifetime online & phone support, including installation assistance, training, and access to our technical team. We’re here to help you get up and running quickly -and keep you running reliably.

Can I integrate the LANDR 500 into my existing production workflow?

Yes. The machine supports standard file formats (.gcode/.stl/.3mf) and can easily integrate into digital manufacturing environments. It’s designed to fit within R&D departments, production cells, or tool rooms as part of a larger workflow.

Is the LANDR 500 available in custom configurations?

Yes — we can tailor the LANDR 500 to meet specific requirements, including increased temperature chambers, dual extrusion, custom build sizes, or material-specific upgrades. Speak to our team for a spec aligned to your application.

What slicer or software does the LANDR 500 use?

The LANDR 500 does have come with its own Slicer that is based on Orca Slicer & is completely open-source.

It is also compatible with industry-standard slicing software including Orca Slicer, Ultimaker Cura, PrusaSlicer, and Simplify3D. We provide custom machine profiles and recommended settings to help you get reliable, high-quality prints from day one.

Because the LANDR 500 uses open G-code, you’re free to use whichever slicer best fits your workflow - with no proprietary restrictions or locked ecosystems.