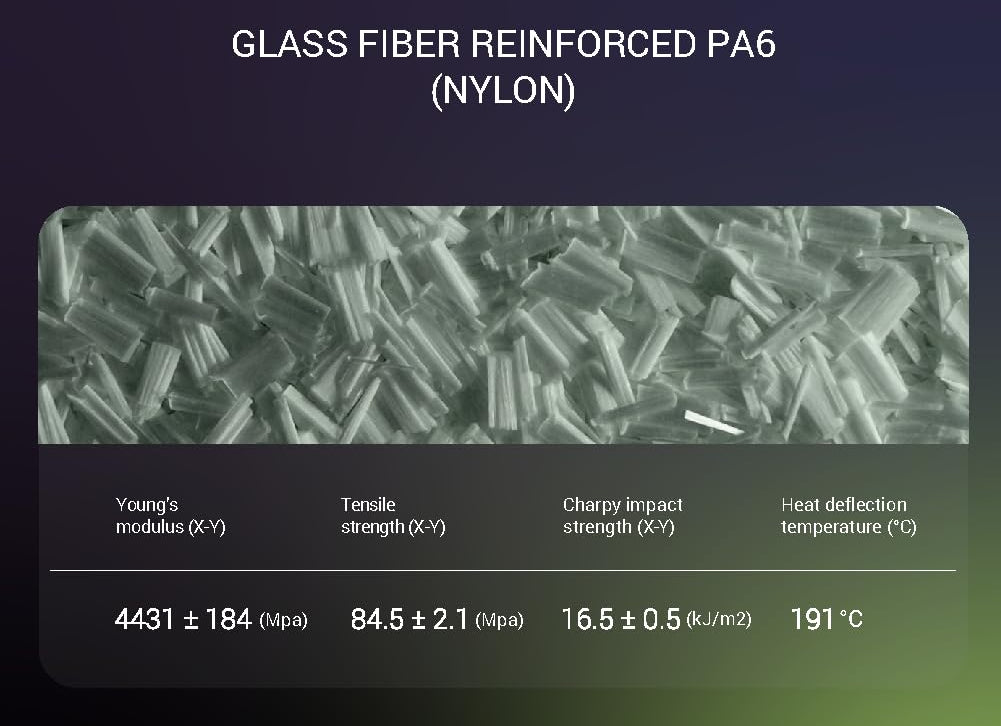

Fiberon PA6-GF25

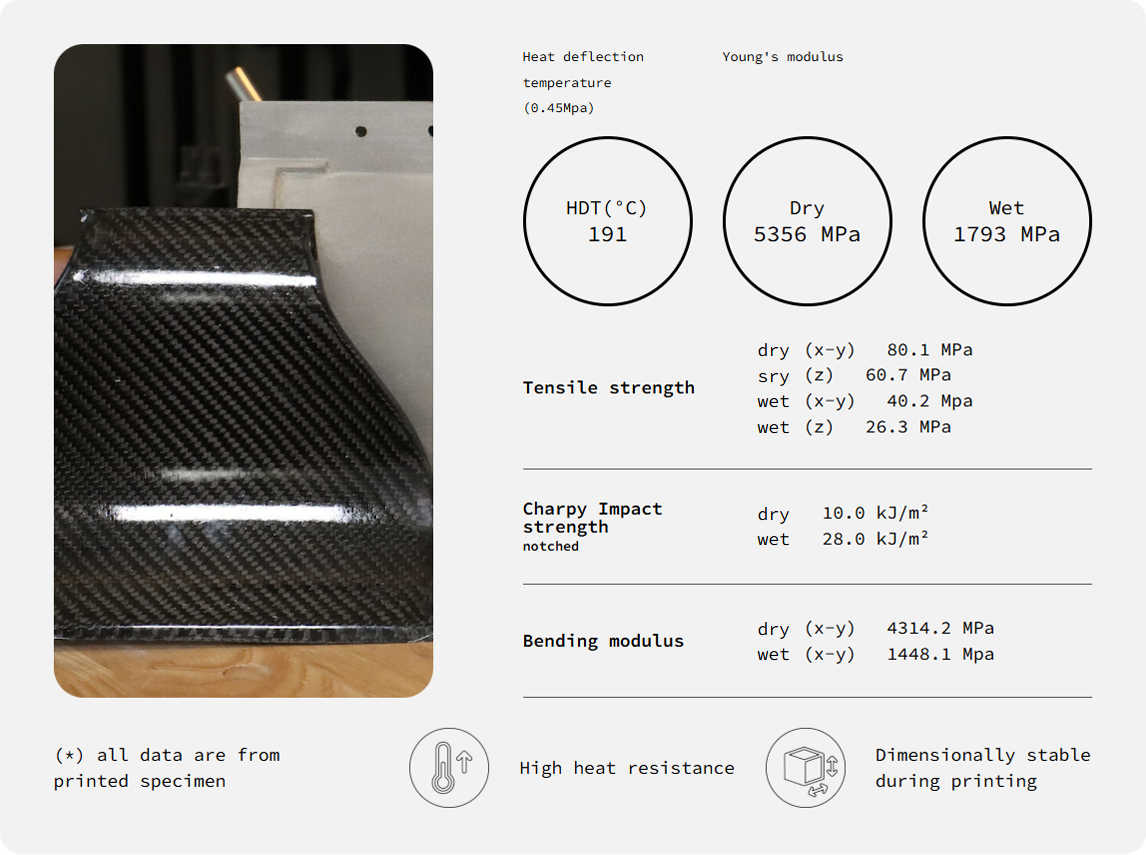

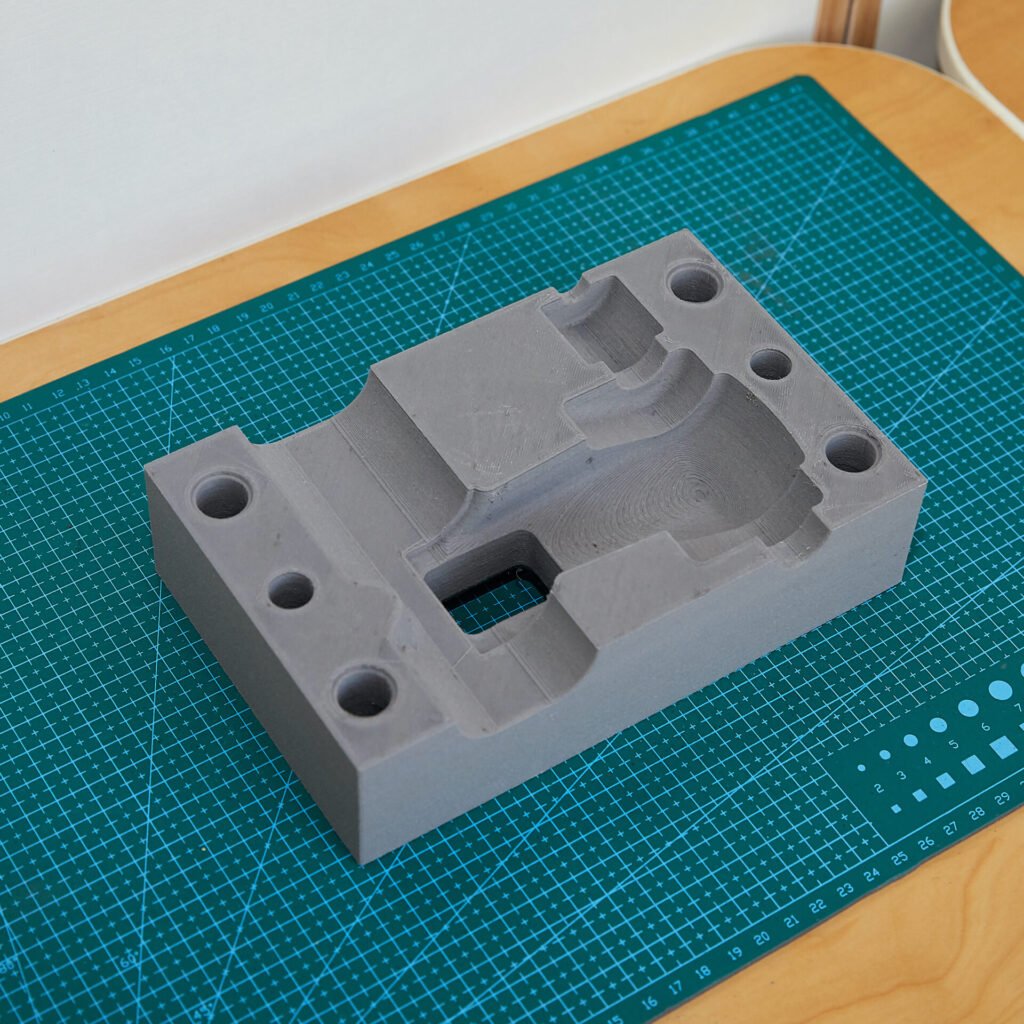

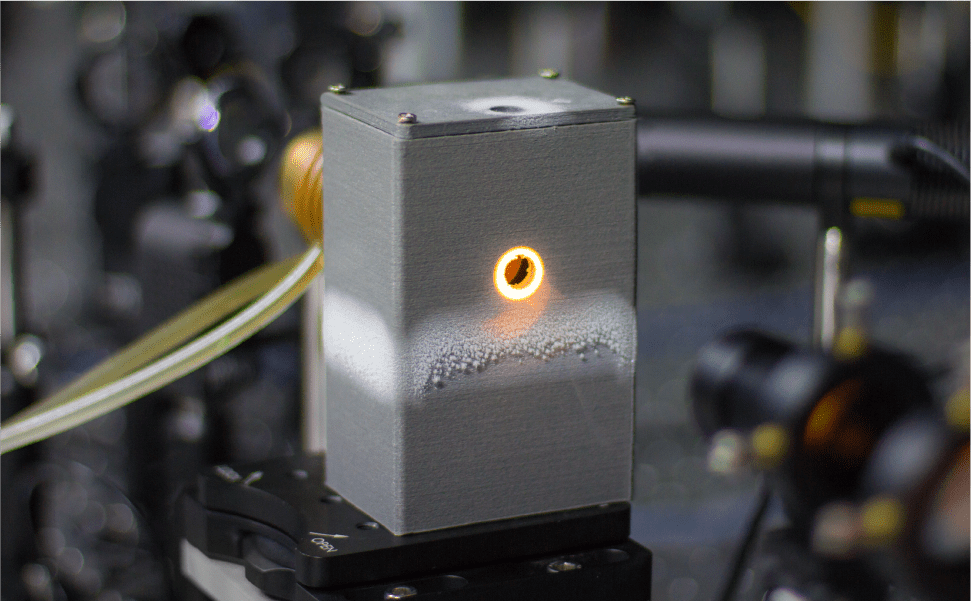

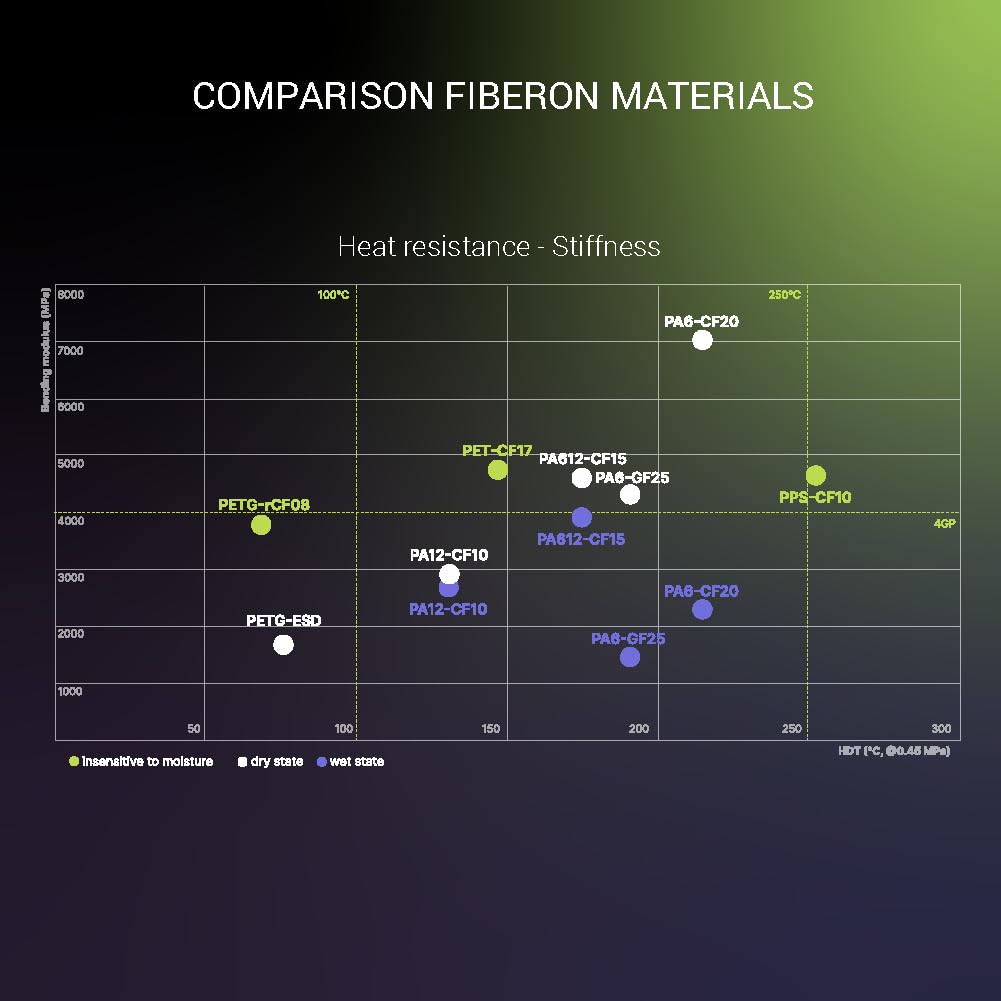

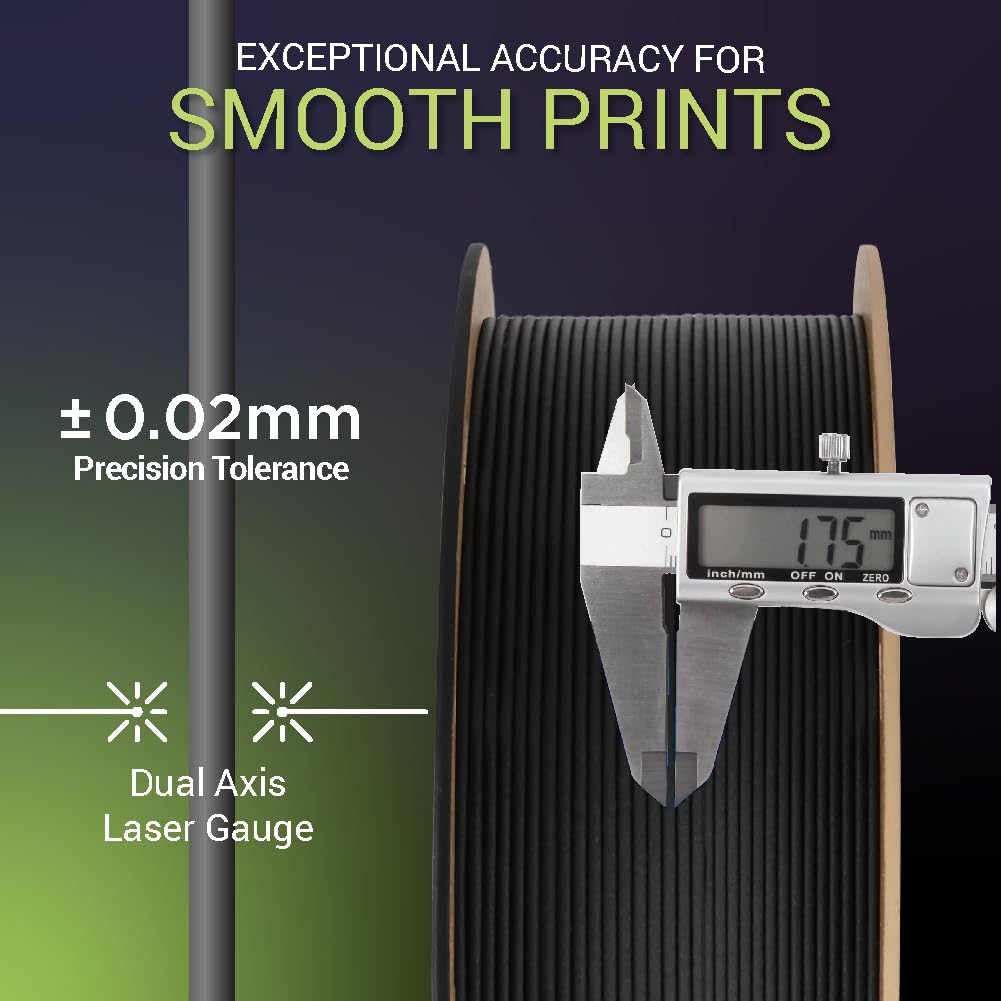

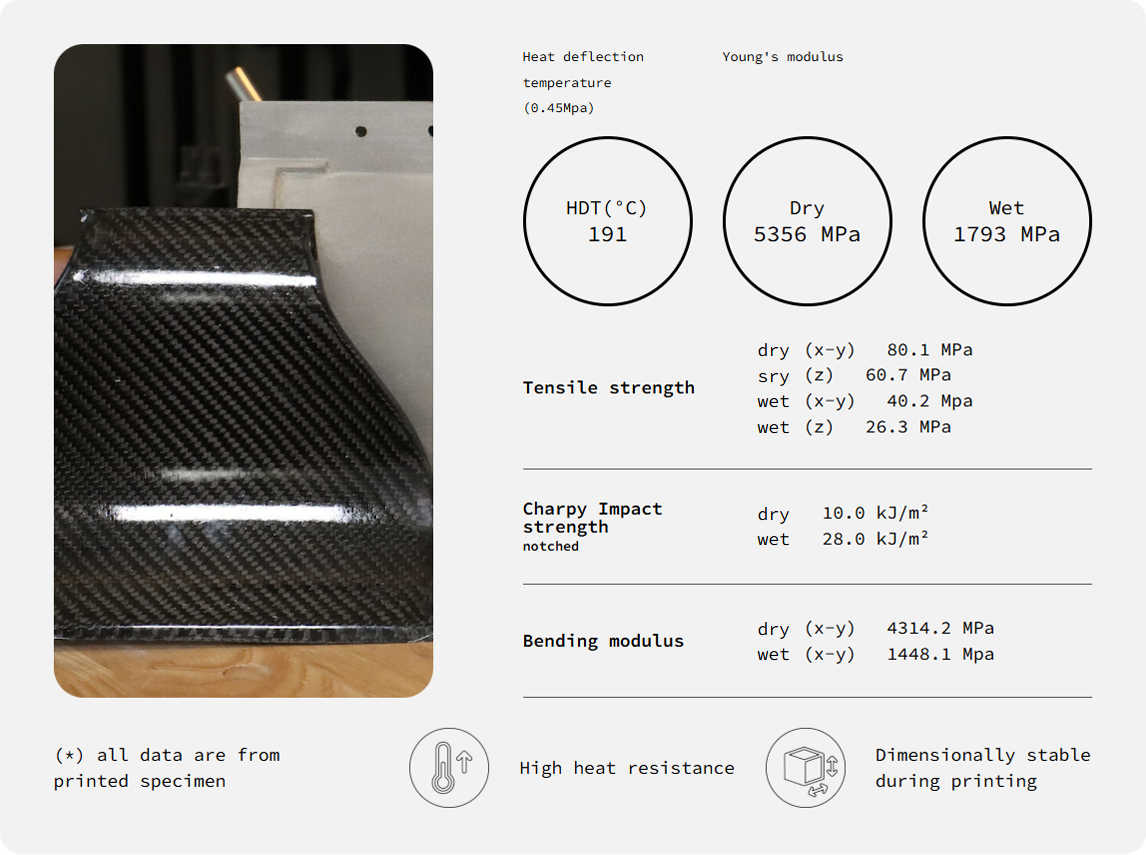

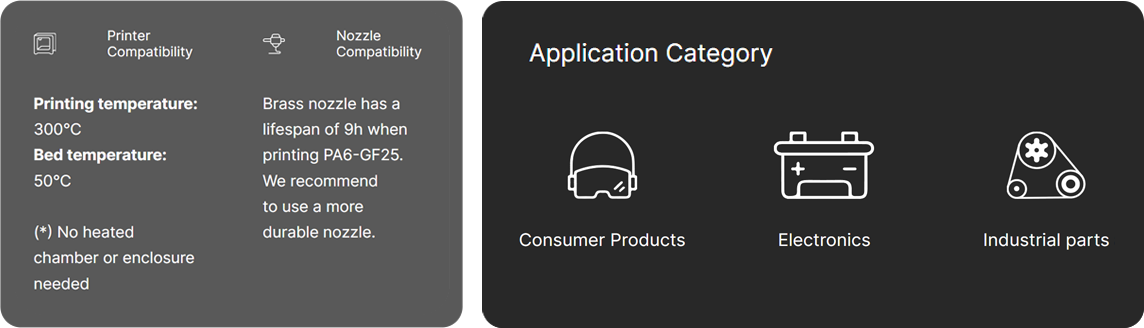

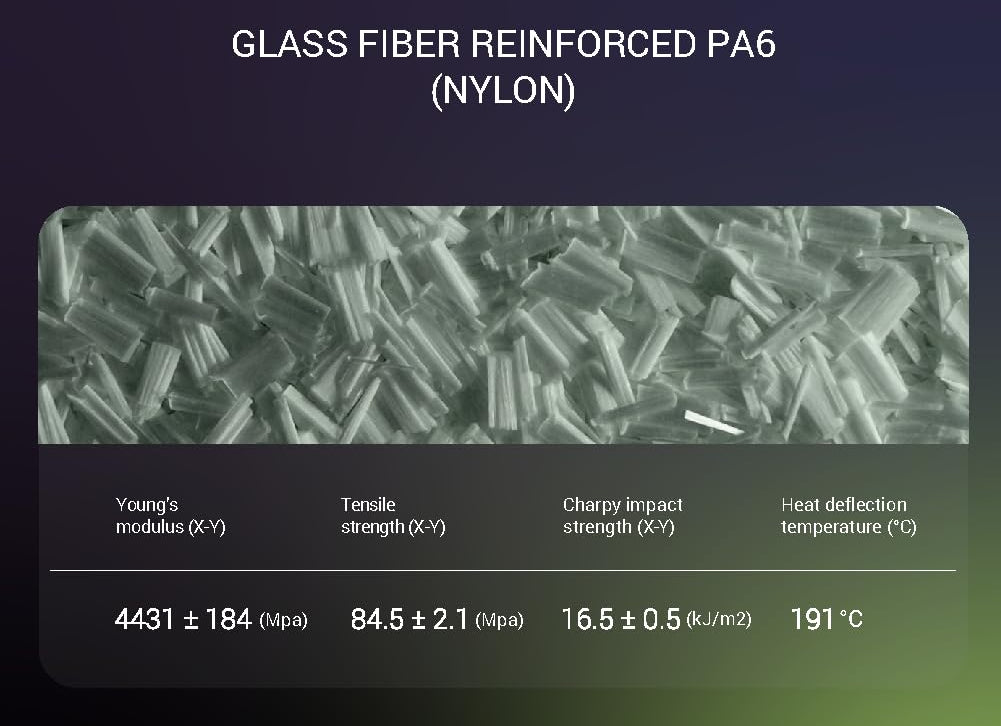

Fiberon™ PA6-GF25 is a glass fiber reinforced Nylon 6 filament. The material exhibits excellent thermal and mechanical properties without sacrificing the layer adhesion or printability. Fiberon™ PA6-GF25 is strong, durable and features a heat deflection temperature of 191°C. It can be used in applications where stiffness and durability are paramount.

FIBERON-PA6-GF25-500

FAQs - FIBERON PA6-GF25

What is the percentage of the Glass Fiber content in Fibero PA6-GF25?

It contains 25 wt% Glass Fibers.

Do PA6-GF25 prints need annealing? What are the annealing conditions?

We strongly recommend 100°C, 10h annealing to achieve the best performance of the material.

Why should we not exceed 50°C on the bed temperature? Isn't this too low for all other carbon nylon filaments?

Our revolutionary Warp-Free technology has been developed to overcome the barriers of printing difficulties and enhance dimensional stability for Nylon based products. With this innovative solution, our nylon products can be printed at lower bed temperatures without experiencing warpage issues. To maintain the integrity of the Warp-Free technology and prevent warpage, it is advised not to exceed a temperature of 50°Ê when using Fiberon™ PA6-GF25. Higher temperatures can invalidate the Warp-Free technology and accelerate the crystallization speed of polyamide polymers, resulting in potential warping issues. In comparison to competitive products, our filaments exhibit superior dimensional stability, providing an exceptional printing experience.

Does the LANDR 500 have pre-set Fiberon Profiles Already?

Yes the LANDR 500 comes with pre-set profiles for all FIBERON & Polymaker materials and many more!

Will the 3kg reel fit into my LANDR Filament Dryer?

Yes absolutely! The 3kg reels fit well into the LANDR Filament Dryer which can also anneal the parts after printed!

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.