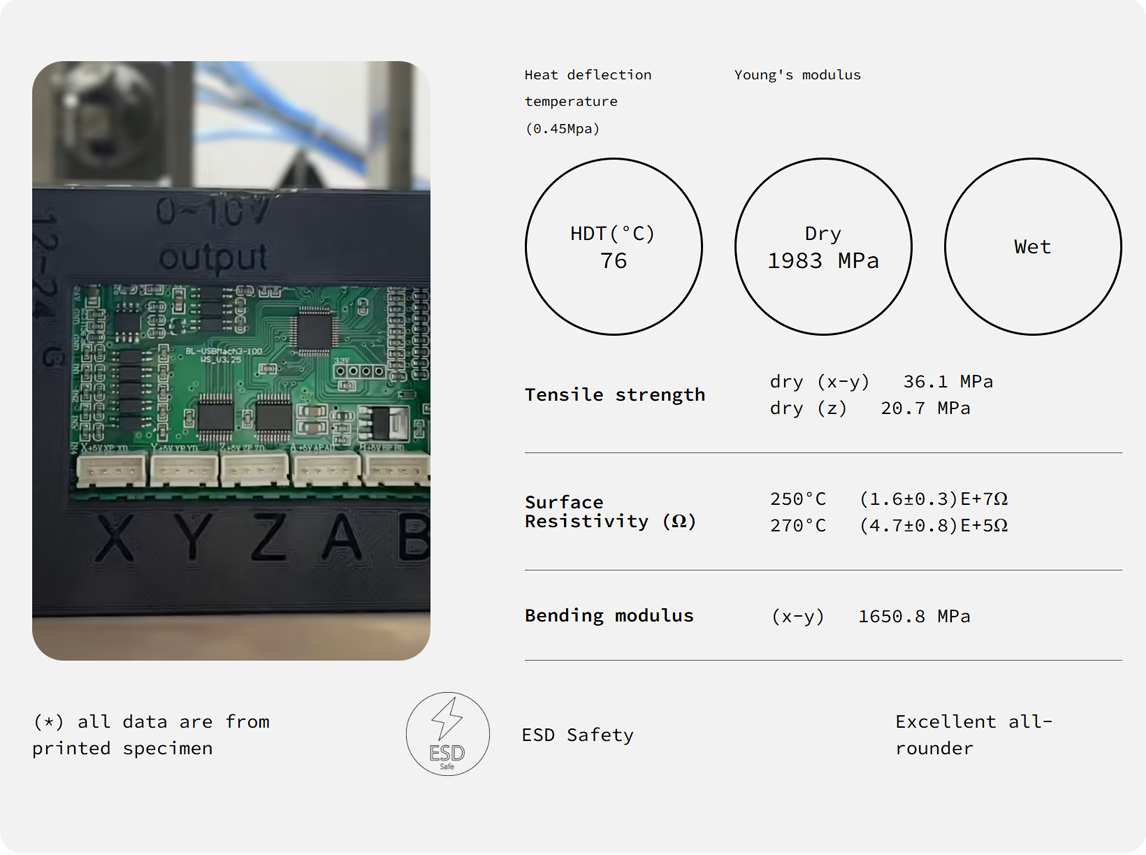

Fiberon PETG-ESD

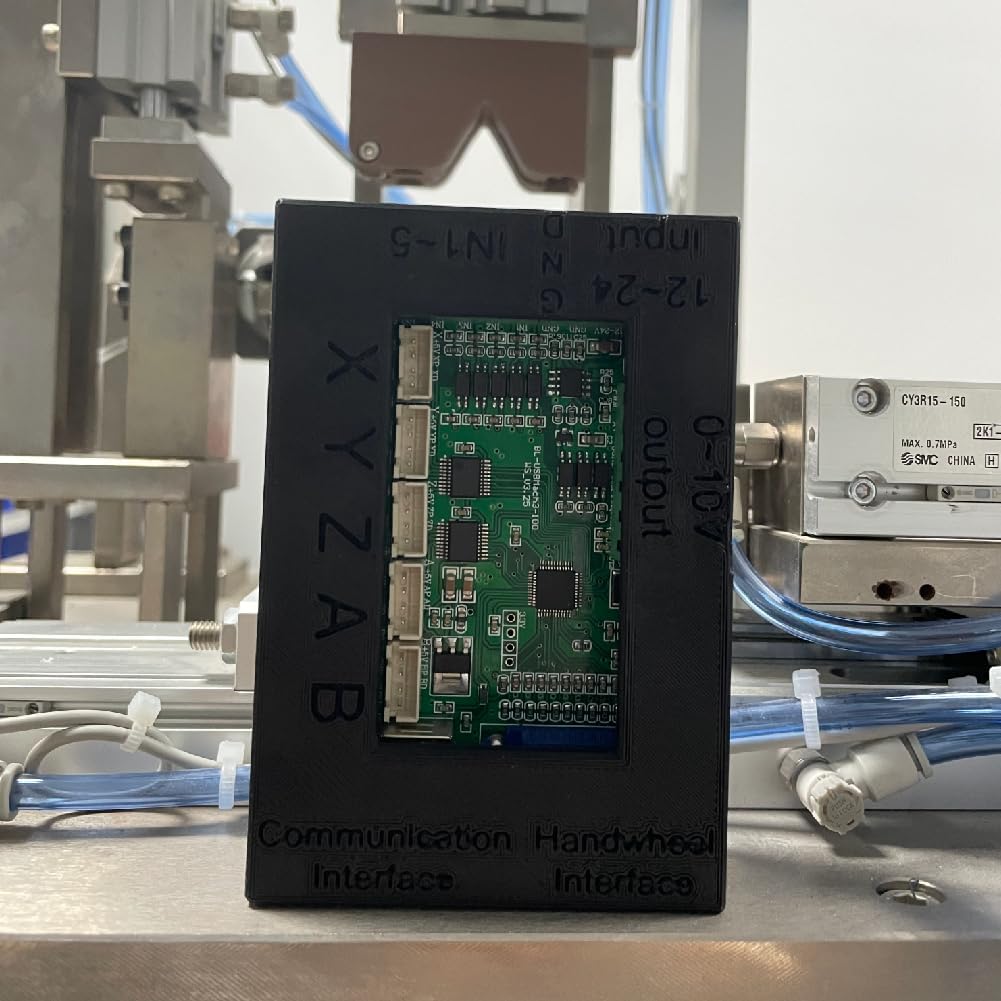

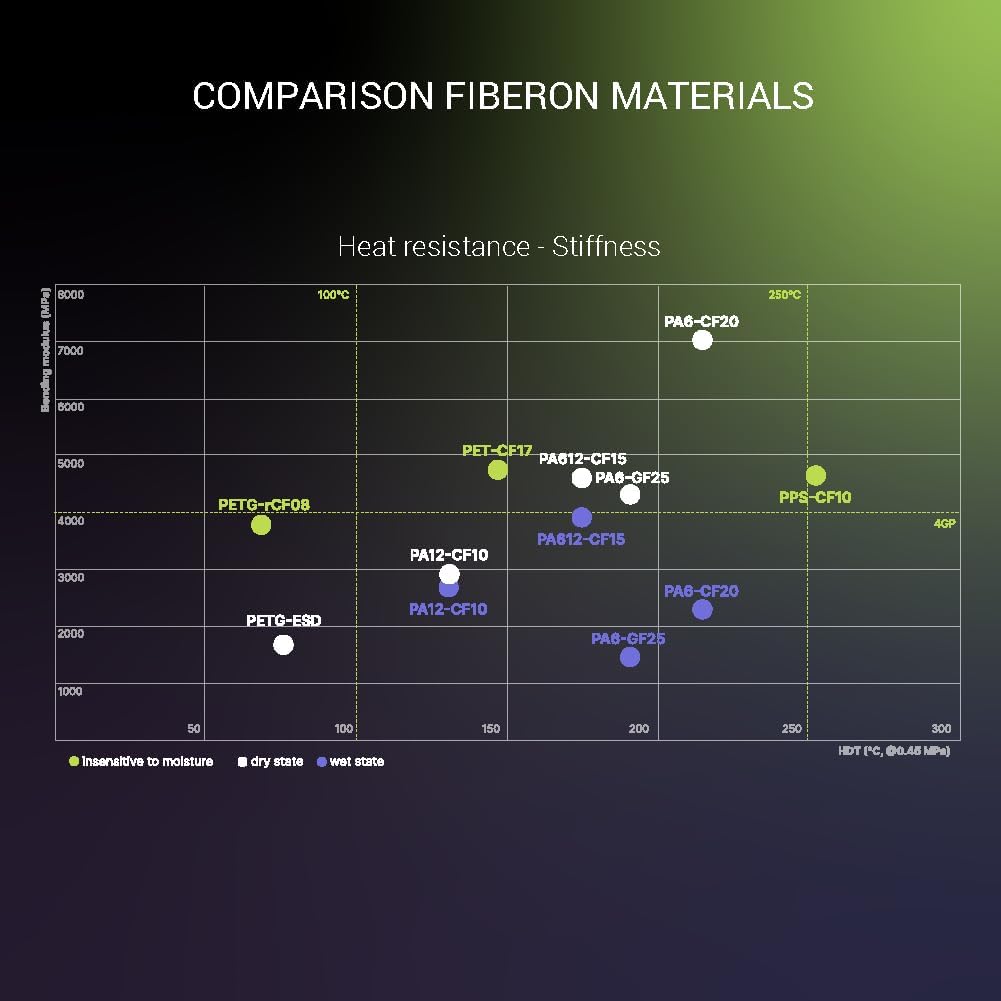

Fiberon™ PA612-ESD is a next-generation nylon composite filament engineered with carbon nanotubes and carbon fibers for enhanced mechanical durability and electrostatic dissipation. Protect your sensitive electronics by 3D printing ESD housings or streamline your production process with ESD safe jigs & fixtures that are not only tough but also heat resistant to 157°C.

FAQs - FIBERON PETG-ESD

What is PETG-ESD?

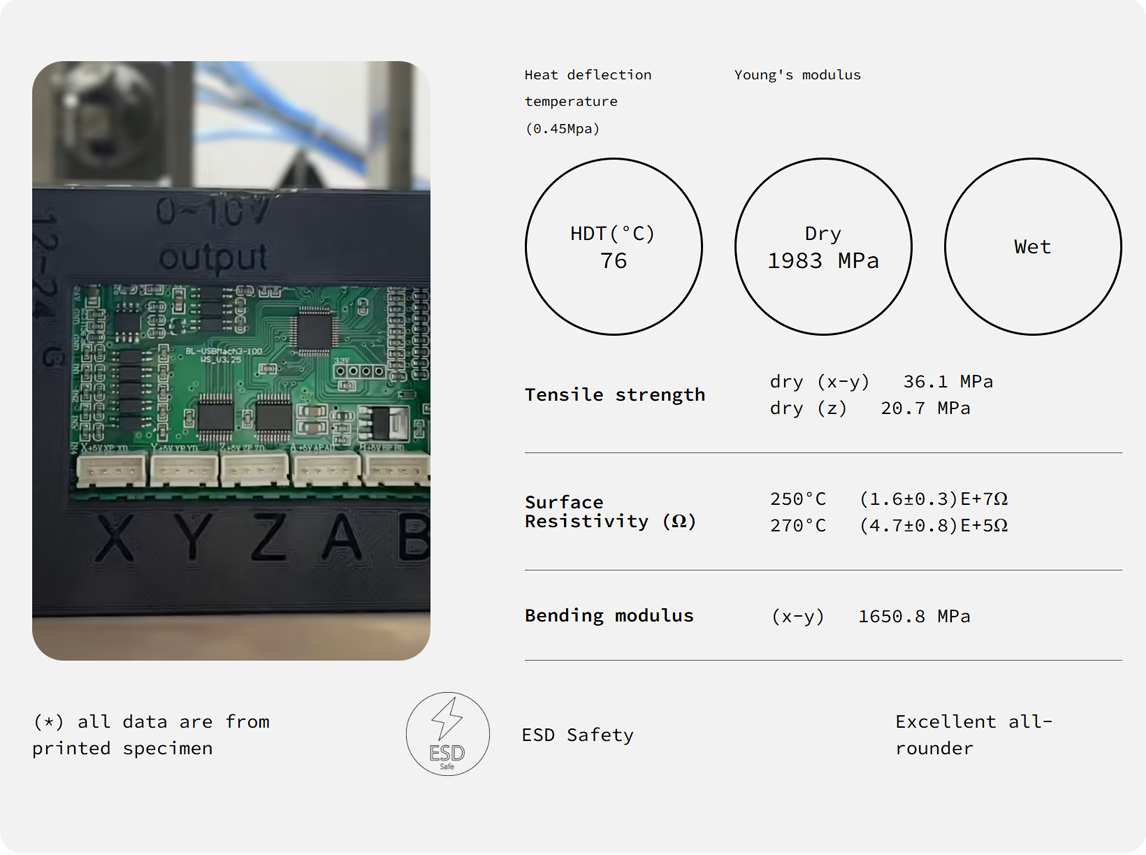

PETG-ESD combines the properties of PETG with the ability to control electrostatic discharge, making it a suitable material for applications requiring ESD protection, such as electronic component packaging, fixtures, jigs, or assembly tools used in ESD-sensitive environments.

What should I pay attention to when printing Fiberon™ PETG-ESD?

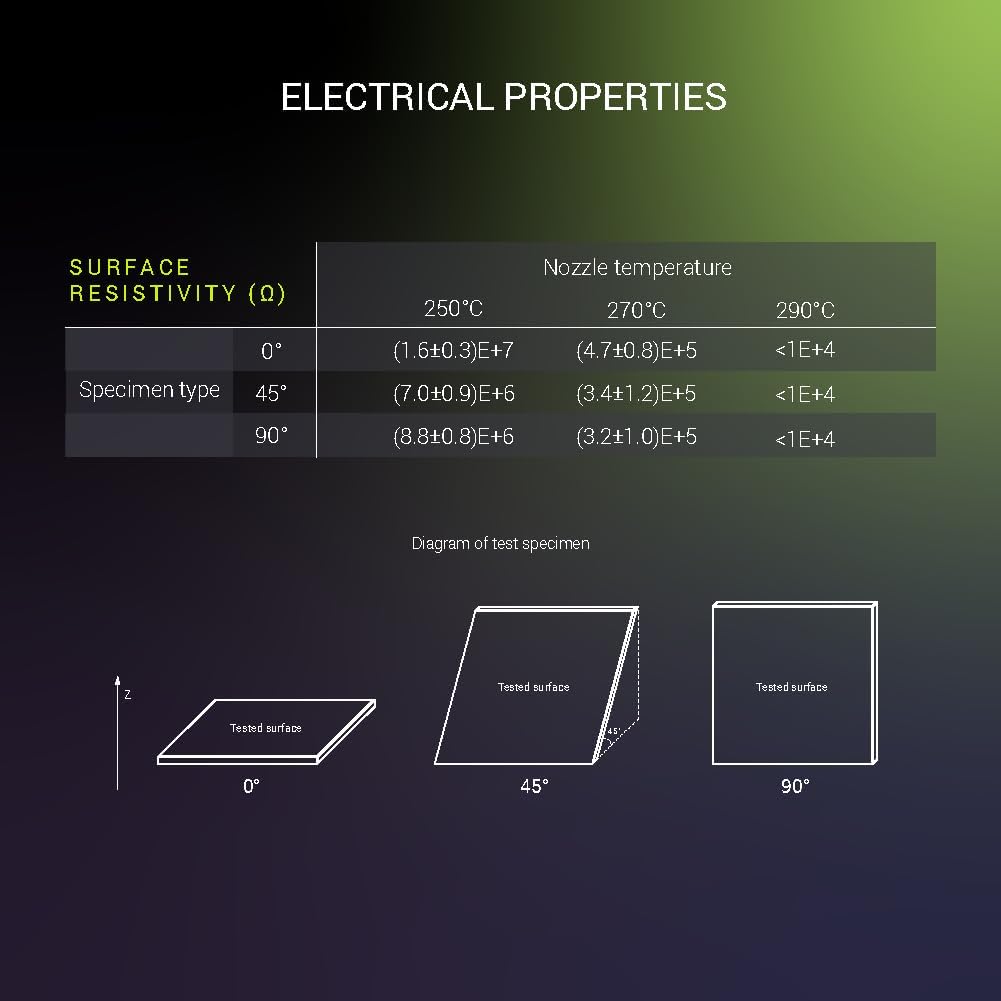

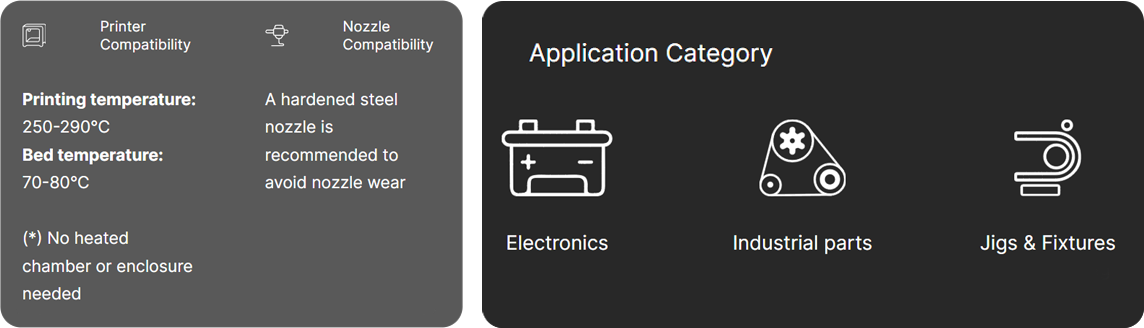

To ensure the ESD (Electrostatic Discharge) property of printed parts when using Fiberon™ PETG-ESD, it is recommended to print at a minimum temperature of 250°C, moreover, because of the added carbon nanotubes, please use a hardened steel nozzle.

Do PETG-ESD prints need to be annealed? What should be noted when using them?

The material can be used without annealing. Please note that drying at 65°C for 3h before use will help achieve better printing performances.

Does the LANDR 500 have pre-set Fiberon Profiles Already?

Yes the LANDR 500 comes with pre-set profiles for all FIBERON & Polymaker materials and many more!

Will the 3kg reel fit into my LANDR Filament Dryer?

Yes absolutely! The 3kg reels fit well into the LANDR Filament Dryer which can also anneal the parts after printed!

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.